All-Weather RVs: Part 2

Four Season RV-ing

What makes a 4-Seasons RV a comfortable “home-away-from-home” that can withstand harsh weather conditions from scorching sun to snowy winter ......

In this presentation, we would like to discuss basic elements of what makes a given RV the true All-Seasons /All-Weather unit.

In the first part of this presentation (see --> Four Season RVs), we defined the following factors defining all-weather readiness of an RV:

- Body construction (thermal insulation, windows, underbelly …)

- Water freezing protection (water lines, holding tanks, drain valves ..)

- Efficient climate control (heating, cooling, venting, condensation…)

- Rain protection

Below we continue with Body Construction:

Thermal Insulation: Siding

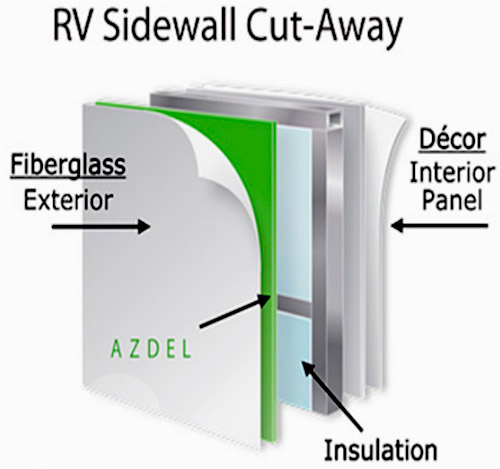

The most common solutions for RV siding are laminated sheets of aluminum or gel coated fiberglass. Also popular are panels of laminated luan or Azdel as they are used anyhow to add strength to the “box”.

Luan (Lauan) plywood is very similar to the traditional one. Its main advantage is substantially lower weight - critical for RVs in the era when "Lightweight" is a word of the year (actually for the years ahead)

The luan (sometimes also spelled “lauan”) is a plywood made from tropical (South-Asian) trees. It is the preferred solution over traditional hardwood plywood due to its significantly lower weight so crucial in modern RV industry. Typically, it comes in ¼ inch panels either laminated (if exposed to weather elements) or just as raw panels if covered by siding. As mentioned earlier, use of wood in all-weather RVs is not the best practice due to the risk of rot and mold. While its use is less critical in traditional “summer” RVs, winter temperatures will cause high level of condensation on any element exposed to exterior temperatures what will be highly destructive to any sort of wood.

An example of an RV sidewall with Azdel

Azdel is a thermoplastic composite material efficiently replacing wood (plywood) in construction of the RV box. It is stronger, lighter and provides higher R-value than the equivalent luan panel at the same time eliminating possibility of mold, mildew and rot. Given these facts, Azdel is the material of choice for “All-Weather” RVs. Unfortunately, Azdel’s higher cost so far limits its widespread use in the RV industry.

If it comes to the choice between aluminum and fiberglass siding, the preference should go to multilayer fiberglass. The aluminum is simply good heat conductor while the fiberglass is a thermal insulator. While due to small thickness of aluminum sheets (0.04” max) it will NOT be a dominating factor in overall thermal barrier, it certainly will have some negative impact, especially in windy winter conditions.

Another important argument for multilayer fiberglass siding is its “continuous seamlessness”. In contrast, the aluminum sheets are attached to the frame by rivets or metal fasteners what weakens the overall integrity of the “box” structure making it prone to leaks.

Insulation of exterior compartments

Exterior compartments in all-weather RVs usually benefit from the fact that the underbelly is enclosed and heated. Obviously, there is no need to keep there “room” temperature (it will be costly requirement), however it is good practice to prevent stored objects from icy weather. Part of the protection are insulated compartment doors and good seals. If this is not the case, try to find model where at least the main pass-through storage meets these requirements.

Windows:

RV windows, similarly as their “residential siblings” are weakest spots (largest sources of the heat loss/heat penetration) in RV’s thermal protection barrier. And honestly there is no good solution to the conflicting requirements of having large panoramic windows and at the same time low energy bills.

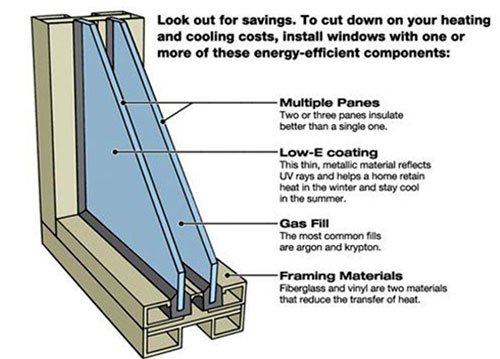

Construction of the thermal, dual-pane window (Courtesy of Roxy Glass)

Currently, the only viable solution proposed by RV industry are “Dual-pane” windows. Technically speaking, the dual pane window consists of two hermetically sealed plates of glass (panes) with a special gas in between them. The gas must be neutral (for safety reasons) and have better thermal properties (higher R-value) than the air. Practical choices are Argon (R-value about 1.5 times higher than air) and Krypton (R correspondingly about 3-times higher than air). Unfortunately, Krypton is much more expensive than Argon so its use by RV industry is rather limited to luxurious rigs. Additional factors improving R-factor of windows are: low emission glass and reflective coating (thin metal film). Needless to say, that equally important is a low conductivity framing (fiberglass or vinyl instead of aluminum). Usually RV windows (regardless if they are dual- or single pane) are dark-tinted. Dark tint not only offers better privacy but also reflects some heat adding extra benefits

How the numbers look in practice? Well, the typical home window may have R-value of 1 to 2 (maximum). However, replacing air with Argon, traditional glass with its low-E version and applying reflective coating may increase R value to the range of 4-5. It’s still not impressive compared to the R-values of the “box”, but hey, by far better than the R-values of traditional, single pane windows.

In some demanding cases (for example residential homes in Alaska) you may see triple-pane windows. While they offer increased thermal insulation (higher R-value) they are simply too heavy and thick for application in RV industry. In fact, the dual-pane windows already add significant extra weight to the RV.

Skylights

Most RVs (even medium sized models) include at least one (if not more) skylights. By definition, they are placed in ceilings at “strategic” locations throughout the RV like bathroom, galley, bedroom. Well, when looking for all-weather RV you may have to lower your expectations. As mentioned above, the ceiling should have the highest level of thermal insulation. In a summer, the roof is directly exposed to the sun so the insulation must be highly efficient to prevent infiltration of the heat. Correspondingly in a winter, the interior heat will accumulate near the ceiling, so the mentioned insulation must prevent the heat from escaping outside. The bottom line is: in all-weather RVs the R-value of roof’s insulation is the highest one (see above typical numbers) and any “hole” (weak spot) in the ceiling’s thermal barrier has serious effects. That’s why usually all-weather RVs have limited number of skylights (if any). Those installed should be also dual-pane ones!

It’s worth to mention that dual-pane windows have good sound-proofing properties, (something that can be priceless on a busy campground)!

Note: This clear thermal improvement comes at the cost. And it is the longevity of dual-pane windows. When installed in residential homes, they may last for 12 to 20 years. However, RVs bring the extra stress due to inevitable shocks and vibration inexistent in “stationary” applications. As the result, the dual pane windows may lose their hermeticity much faster (and certainly they will). And the consequences are not user friendly. You may still be able to live with higher energy bills (or lower comfort), but for sure you will have hard time to accept foggy windows. And this is what will happen when exterior air with some level of humidity will infiltrate the interior gap between glass panes. Sorry to say it, but the only practical solution in such case is to change the windows but it is a costly event.

Practical notes:

- RV’s high quality/“soft suspension” will increase the lifespan of dual-pane windows

- Off-road RV-ing will accelerate the degradation of dual-pane windows.

Unfortunately, there is no much you can do about it so the best advice is: enjoy your trips as long as you can.

Well, there are still some good “grand-mama”-era habits that can help and they do not cost much. The shades over windows will always add into overall R-value of the thermal insulation. So, when you are NOT watching the beauty of the surrounding nature, gazing at the nightly sky in the comfort of your RV’s recliner (theater seat, sofa, bed….) use the shades. They will decrease the heat convection/radiation between the window and the interior of your RV. While it may be a “tough call” during the day in nature, you should certainly do it (not only for the privacy reason) during cold nights.

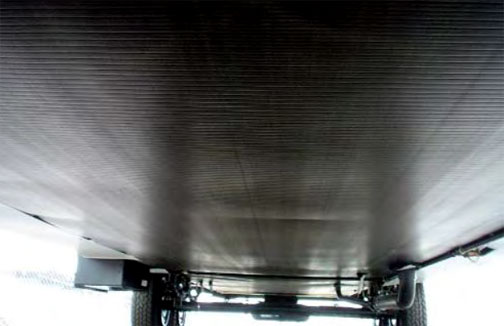

Underbelly

Underbelly houses almost all vital RV systems of which in all-weather models some most critical are plumbing, holding tanks, dumping valves, utility hook-ups including external shower etc… In general it is everything containing water due to the risk of destruction when frozen. That is why every all-weather RV must have an enclosed, thermally insulated and heated underbelly. The heat may be provided by running “non-insulated” main heating ducts through the underbelly (and some storage compartments) or by a dedicated heat distribution system.

An example of an enclosed underbelly - here Canyon Trailer (Note: it's not an all-weather RV)

However, the hot air circulating system is not enough to prevent potential damage. While on the campground you will certainly turn on your furnace (if needed), but in most cases, it will not happen when on the road (mainly due to security reasons). Long hours on the highway especially in “cold headwind” environment will certainly bring RV’s interior temperature (including the underbelly) down, potentially below the freezing point. That is why each all-weather RV must have a secondary heating system for water installations. Usually these will be heating pads running on an auxiliary battery.

It should be noted that underbelly’s interior temperature does not have to be as high as in RV living sections. It must just offer some reasonable safety margin above the freezing point.

Notes:

- 12V heating pads are preferred over 120Vac ones, because mostly you need them when on the road. The bad news is that given the typically large scale of the water system, you may completely draw down the auxiliary battery!

- To prevent (or at least minimize such probability), the water system needs an extra protection (on top of already mentioned underbelly insulation) and heating pads. Water pipes should be individually covered by foam-pipes (similar like in residential systems) and holding tanks should be wrapped in fiberglass mats. Keep in mind - to make it work, the extra insulation should cover both – water holding elements and their heating pads.

- Skirt protection (when on the campground) will help to keep the underbelly warm at lower energy cost. Skirt’s benefits will be especially visible in icy-wind conditions.

Skirting helps to keep RV warmer

See details at: --> RV skirting

The extra benefits of the enclosed underbelly are: lower aerodynamic drag on the road (so better fuel efficiency), protections from debris (especially important for off-road models) and protection of all “stuff” traditionally mounted under the floor) from rain water, mud etc…. (eventual rust, rot …)

Exterior Steps

In general, steps in RVs are often forgotten (in other words, it is assumed that are where they supposed to be and there is no reason to worry about). While it may be justified approach in traditional summer RVs, it will be very wrong in the case of all-weather models. Accumulated snow and/or ice can make them a “deadly” trap. So here some suggestions:

- Anti-slippery surface is the minimum requirement

Please note however that the traditional anti-slippery surface offers protection when wet (good for rainy season). Accumulated snow and/or icy-rain will make it mostly useless.

- Robust handrail offering good support is the MUST.

- Steps’ surface preventing (or at least minimizing) accumulation of the snow is preferred (sort of metal grid)

Needless to mention that the aluminum steps have clear advantage over prone to corrosion steel ones.

Awnings and Slide-out Toppers.

Awnings are greatly appreciated during traditional RV-ing season. They offer shade protecting from scorching sun and “shelter” in the case or rain. Protection from direct exposure to the sun is also beneficial for the RV itself (precisely for the A/C system). It simply makes the first “outer” barrier decreasing the heat-stress on sidewalls and more importantly on the weakest spots in RV’s insulation –windows.

During winter season, traditional awnings are rarely used. Exposure to snow (and potentially damaging heavy load), possibility of strong winds – are convincing factors to keep them closed.

The use of slide-out toppers has merits throughout the whole year. In summer, they protect slide-out roof from debris (mainly leaves and small branches when parking under the trees). They also provide “some” heat-barrier protecting mentioned roof from direct exposure to the sun. The use of slide-out toppers in winter is a bit trickier. The accumulated snow (or even worse- icy snow) on the slide-out roof will make its retracting process at best painful if not impossible. It is up to you to decide what is easier – remove the snow from the topper or from the slide-out roof. However one thing is clear – the damage to the slide-out (especially seals) may be much more costly than the potential damage to the toppers.

Note that slide-out toppers are much smaller than their “traditional” cousins on the sidewalls so they are better prepared to survive the snow and winds.

See also --> Best winter Travel Trailers

Well, we just finished the short overview of Construction Requirements for an All-weather RV. Next are coming the following topics:

- Water freezing protection (water lines, holding tanks, drain valves ..)

- Efficient climate control (heating, cooling, venting, condensation…)

- Rain protection

Please continue at: --> Four-Seasons RV: Climate Control

.